Friday, January 24, 2025

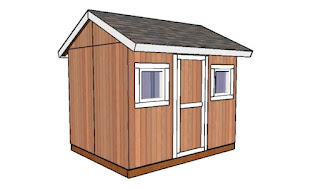

Free 8x10 shed designs for a compact outdoor storage solution

Free 8x10 Shed Designs for a Compact Outdoor Storage Solution

The need for efficient and aesthetically pleasing outdoor storage solutions is paramount for homeowners seeking to maximize their property's functionality. An 8x10 shed offers a compelling balance between compact footprint and ample storage capacity, ideal for various applications, from gardening tools and equipment to recreational items and seasonal decorations. This article explores several free 8x10 shed designs, emphasizing practicality, durability, and cost-effectiveness. We will delve into design considerations, material selection, and construction techniques, empowering readers to embark on their DIY shed-building projects with confidence.

Design Considerations for an 8x10 Shed

Before commencing the construction of your 8x10 shed, careful planning is crucial to ensure the project's success. Several key design aspects warrant consideration:

Site Selection and Preparation

Site selection is paramount. Consider factors such as accessibility, proximity to utilities, sun exposure, and drainage. Adequate space around the shed is essential for ease of access and future maintenance. Proper site preparation involves leveling the ground, removing debris, and potentially adding a gravel base for enhanced drainage and stability. Local building codes should also be consulted to ensure compliance with regulations pertaining to shed placement and size.

Foundation Options

The choice of foundation significantly impacts the shed's longevity and stability. Several options exist, each with its own advantages and disadvantages:

- Concrete Slab: Offers excellent stability and durability, but is relatively expensive and requires specialized skills for pouring.

- Gravel Base: A cost-effective and simple solution, particularly suitable for well-drained soil. Provides adequate drainage but may require more maintenance over time.

- Pressure-Treated Skids or Piers: A budget-friendly option that elevates the shed off the ground, improving drainage and minimizing ground contact. This approach requires precise leveling for structural integrity.

Shed Style and Aesthetics

Numerous design styles are available for 8x10 sheds, allowing for customization to match existing architectural aesthetics. Consider:

- A-Frame Shed: Offers a classic and simple design, maximizing headroom while minimizing material costs.

- Gable Shed: Features a triangular roof design, providing increased headroom and improved ventilation.

- Saltbox Shed: Characterized by an asymmetrical roofline, offering a unique aesthetic appeal and greater storage space under the longer roof slope.

The choice of exterior cladding, such as wood siding, metal sheeting, or vinyl panels, significantly influences the shed's appearance and maintenance requirements.

Door and Window Placement

Strategic placement of doors and windows maximizes functionality and ventilation. Consider the following:

- Door Size and Location: Ensure adequate clearance for accessing stored items. A double door can be beneficial for larger items.

- Window Placement: Windows improve natural light and ventilation within the shed. Consider placement to optimize light entry and minimize direct sunlight on stored items.

Free 8x10 Shed Plans and Resources

Numerous online resources provide free 8x10 shed plans, offering detailed blueprints and construction guides. These resources often include:

- Detailed Drawings: Illustrating dimensions, material lists, and cutting diagrams.

- Step-by-Step Instructions: Providing a comprehensive guide to the construction process.

- Material Lists: Specifying the quantity and type of materials required.

It is crucial to carefully review and understand the provided plans before commencing construction. Pay close attention to details such as framing techniques, roofing methods, and fastening procedures. Many free plans are available on websites dedicated to DIY projects and home improvement.

Material Selection and Cost Considerations

Material selection is a critical aspect of shed construction, directly influencing the structure's durability, cost, and aesthetics. Common materials include:

Framing Materials

Pressure-treated lumber is typically preferred for its resistance to rot and insect damage. Consider using 2x4s or 2x6s for framing depending on the desired strength and snow load requirements.

Exterior Cladding

Options include wood siding, vinyl panels, and metal sheeting. Wood siding provides a classic and aesthetically pleasing look, but requires regular maintenance. Vinyl panels are low-maintenance but may not be as durable as wood. Metal sheeting offers exceptional durability and weather resistance.

Roofing Materials

Asphalt shingles are a common and cost-effective roofing option. Metal roofing offers greater durability and longevity but is generally more expensive. Consider local climate conditions when choosing roofing materials.

Other Materials

Other materials required include screws, nails, plywood for sheathing, doors, windows, and possibly a concrete or gravel foundation.

Cost Considerations: While free plans eliminate design fees, material costs can vary significantly depending on location and material choices. Creating a detailed material list and obtaining price quotes from local suppliers is essential for accurate budgeting.

Construction Techniques and Best Practices

Constructing an 8x10 shed requires careful attention to detail and adherence to best practices. Key steps include:

Foundation Construction

Begin by constructing the foundation, carefully following the chosen method (concrete slab, gravel base, or pressure-treated skids). Ensure proper leveling for stability.

Framing and Sheathing

Assemble the wall and roof frames according to the provided plans, paying close attention to squareness and alignment. Apply sheathing to the walls and roof to provide a stable base for the exterior cladding.

Exterior Cladding and Roofing

Install the chosen exterior cladding, ensuring proper overlap and sealing to prevent water infiltration. Install the roofing materials according to manufacturer instructions.

Door and Window Installation

Install the doors and windows, ensuring proper sealing and weatherproofing.

Finishing Touches

Complete the project with finishing touches such as trim work, painting, and landscaping.

Remember to prioritize safety throughout the construction process. Wear appropriate safety gear, such as safety glasses, gloves, and hearing protection. Follow all manufacturer instructions for materials and tools.

By carefully planning, selecting appropriate materials, and following best practices, building an 8x10 shed can be a rewarding DIY project, providing a valuable addition to your property.

Affordable shed plans for first-timers

Affordable Shed Plans for First-Time Builders: A Comprehensive Guide

Constructing a shed can be a rewarding project, enhancing property value and providing valuable storage space. However, the cost of professional construction can be prohibitive. This comprehensive guide offers detailed strategies for first-time builders seeking affordable shed plans, encompassing design considerations, material sourcing, and construction techniques to minimize expenses without compromising structural integrity or aesthetic appeal.

I. Planning and Design: Laying the Foundation for Affordability

Careful planning is paramount in achieving cost-effective shed construction. Poor planning often leads to material waste, unforeseen expenses, and project delays. The initial design phase directly impacts the final cost, hence meticulous consideration is crucial.

A. Defining Your Shed's Purpose and Size

Before commencing any design work, clearly define the intended purpose of your shed. Will it serve as a simple storage unit, a workshop, or a combination thereof? This dictates the required size and internal features. Avoid oversizing; a larger shed inherently requires more materials and labor. Begin with a modest design and scale up only if absolutely necessary.

B. Selecting Suitable Shed Styles

Numerous shed styles exist, each with varying material requirements and complexity. Simple designs, such as gable or lean-to sheds, generally prove more cost-effective than intricate designs. Gable sheds, characterized by their triangular roof, offer good ventilation and ample headroom. Lean-to sheds, relying on an existing structure for support, minimize material usage and construction time. Research various styles and select the one best suited to your needs and budget.

C. Material Selection: Optimizing Cost and Durability

Material selection significantly affects the overall cost. While premium materials offer superior longevity, they come at a premium price. Consider cost-effective yet durable alternatives. Pressure-treated lumber provides excellent resistance to rot and insects, making it a suitable choice for the shed's framing. For siding, vinyl siding or metal sheeting present attractive, low-maintenance options compared to more expensive wood cladding. Roofing material choices should balance cost, durability, and weather resistance; asphalt shingles remain a popular and relatively inexpensive option.

II. Sourcing Materials: Strategies for Budget-Conscious Procurement

Procuring materials at the best possible price requires a strategic approach. Avoid impulse purchases and thoroughly compare prices from various suppliers.

A. Exploring Different Suppliers

Don't limit yourself to large home improvement stores. Consider local lumber yards, salvage yards, and even online retailers. Local lumber yards often offer competitive pricing and personalized service, while salvage yards can provide reclaimed materials at significantly reduced costs. Online retailers offer convenience and the ability to compare prices across a wider range of suppliers. Always compare quotes from multiple sources before making any purchases.

B. Utilizing Reclaimed or Recycled Materials

Incorporating reclaimed or recycled materials offers substantial cost savings and environmental benefits. Salvage yards can provide usable lumber, roofing materials, and even doors and windows at fractions of their original cost. Ensure that reclaimed materials are structurally sound before incorporating them into your shed's construction.

C. Planning Material Purchases to Minimize Waste

Precise planning minimizes material waste. Create detailed cut lists based on your chosen shed plans. This ensures you purchase only the necessary materials, avoiding excess expenditures. Consider using software or online calculators to optimize material usage and minimize waste.

III. Construction Techniques: Practical Steps for Affordable Building

Efficient construction techniques directly contribute to cost savings. Proper planning and execution minimize material waste, labor costs, and potential errors that could necessitate costly repairs.

A. Foundation Considerations: Cost-Effective Options

The foundation forms the base of your shed. While concrete foundations offer durability, they represent a significant expense. Cost-effective alternatives include gravel pads, concrete piers, or even a simple wooden frame set on compacted earth. Choose a foundation suitable to your soil conditions and shed size. Consult local building codes to ensure compliance.

B. Efficient Framing Techniques

Frame construction should be precise and efficient to minimize material waste. Utilize pre-cut lumber whenever possible to streamline the process. Accurate measurements and proper joinery are vital to ensure a strong and stable structure. Consider utilizing simple framing techniques, avoiding overly complex designs that require specialized skills and tools.

C. Utilizing Simple Tools and Techniques

Sophisticated power tools are not always necessary. Many shed construction tasks can be accomplished using basic hand tools, reducing upfront investment in equipment. Prioritize learning fundamental carpentry skills through online tutorials or workshops. This reduces reliance on costly professional labor.

IV. Seeking Assistance and Resources

While DIY shed construction offers significant cost savings, acknowledging limitations is essential. Seek assistance when needed. Consult experienced builders or utilize online forums and resources for guidance on complex aspects of the project.

A. Online Resources and Tutorials

Numerous online resources offer free shed plans, construction guides, and tutorials. Utilize these to enhance your understanding and confidence in the construction process. Thoroughly research and cross-reference information from multiple sources to ensure accuracy.

B. Seeking Advice from Experienced Builders

Consult experienced builders for advice on specific challenges. A brief consultation can often prevent costly mistakes and ensure the structural integrity of your shed. Networking with local builders can provide valuable insights and potentially identify cost-effective material sources.

C. Understanding Local Building Codes and Permits

Familiarize yourself with local building codes and permit requirements before commencing construction. Failure to comply can result in costly fines or even demolition orders. Obtain the necessary permits to ensure your project adheres to local regulations.

By diligently following these guidelines and prioritizing careful planning and execution, first-time builders can successfully construct an affordable and functional shed that meets their needs and enhances their property.

Step-by-step guide to building a secure 8x10 shed with double doors

Building a Secure 8x10 Shed with Double Doors: A Comprehensive Guide

Constructing a secure shed offers peace of mind, knowing your valuable belongings are safe and sound. This guide walks you through building a robust 8x10 shed with double doors, focusing on security features at every stage. We'll cover everything from foundation to finishing touches, ensuring your new shed is as impenetrable as possible.

Planning and Preparation: Laying the Groundwork for Security

Before you even touch a tool, meticulous planning is crucial. Start by obtaining the necessary permits from your local authorities. This seemingly simple step avoids potential legal headaches down the line. Next, choose a location that's easily accessible yet relatively inconspicuous, deterring potential thieves. Consider the ground conditions; a level, well-drained site is essential for a stable foundation. Finally, meticulously plan your shed's layout, considering placement of doors and windows for optimal security and accessibility.

Choosing the Right Materials for Superior Security

The materials you choose directly impact your shed's security. Opt for pressure-treated lumber for the frame â€" its resistance to rot and decay ensures longevity and structural integrity. For the siding, consider strong, durable materials like metal or composite panels. These offer superior protection against forced entry compared to traditional wood siding. Don't skimp on hardware; use heavy-duty hinges, sturdy door handles, and a high-quality lockset designed for exterior use. Remember, the stronger your materials, the more secure your investment.

Foundation and Framing: Building a Solid Base

A secure shed begins with a solid foundation. For an 8x10 shed, a concrete slab provides the best security and stability. Pouring a concrete slab involves excavating the area, adding gravel for drainage, and then pouring and leveling the concrete. Allow ample curing time for the concrete to reach full strength. Once the foundation is set, erect the frame using pressure-treated lumber. Ensure all joints are securely fastened with galvanized screws or bolts â€" no nails! Precise measurements and perfectly square corners are essential for a strong, secure structure.

Reinforcing the Frame for Enhanced Security

To further enhance security, consider adding extra support beams and bracing to the frame. This will significantly increase resistance against attempts to force entry. You can also install metal straps at critical joints to reinforce the structure against strong winds and potential impacts. Pay particular attention to the door frame; it will bear the brunt of any forced entry attempts. Use extra-thick lumber and reinforce it with metal plates for added protection.

Siding and Roofing: Protecting Your Investment

With the frame complete, it's time to clad your shed with the chosen siding material. Whether you opt for metal or composite panels, ensure each panel is securely fastened, leaving no gaps that could be exploited. Overlapping panels adds an extra layer of protection. The roof should be constructed with durable materials like asphalt shingles or metal roofing for weather resistance and security. Properly sealing all seams and joints will prevent water damage and further enhance the shed's overall strength.

Double Doors and Security Features: The Final Touches

Install your double doors using heavy-duty hinges rated for exterior use. Choose doors made from solid core materials, offering superior resistance to forced entry compared to hollow-core doors. Fit a high-quality, multi-point locking system that engages at multiple points along the door frame. Consider adding a deadbolt for extra security. A good quality, weather-resistant lock will ensure your belongings remain safe and sound.

Adding Extra Security Measures

To further enhance security, consider adding the following features:

- Motion-activated security lights: These deter potential intruders.

- Security cameras: Provide visual surveillance and act as a deterrent.

- Ground anchors: Secure the shed to the ground to prevent theft.

- Concealed hinges: Make it more difficult for intruders to remove the doors.

By following these steps, you'll build a secure and durable 8x10 shed that protects your valuables for years to come. Remember, attention to detail and the use of high-quality materials are key to creating a truly secure structure.

How to build a shed with detailed materials list and construction guide

Building Your Dream Shed: A Comprehensive Guide

Building a shed is a rewarding project that allows you to create valuable extra storage space or a dedicated workshop. This guide provides a step-by-step approach, ensuring a sturdy and functional shed perfect for your needs. Remember to always check local building codes and obtain necessary permits before starting your project.

Planning and Design

Choosing the Right Location and Size

First, select a suitable location for your shed. Consider factors like sunlight, proximity to power sources, and access for deliveries. Next, determine the desired dimensions. Think about the items you plan to store and allow ample space for maneuvering. Draw a detailed sketch to visualize your shed's layout, including doors, windows, and shelving.

Materials Selection: Quality Matters

Choosing high-quality materials is crucial for longevity. Opt for pressure-treated lumber to resist rot and insect damage. Consider using thicker boards for the floor and framing for extra strength. Your materials list will vary based on your shed's dimensions but should include:

- Pressure-treated lumber for the foundation, framing, and floor.

- Plywood or OSB for sheathing and roofing.

- Roofing materials (shingles, metal, etc.).

- Exterior siding (vinyl, wood, metal, etc.).

- Doors and windows.

- Nails, screws, and other fasteners.

- Concrete mix (for a concrete foundation).

- Paint or stain (optional).

Foundation Construction

Creating a Level Base

Begin by preparing the ground. Clear the area of vegetation and debris. Level the ground using a shovel and rake. For a more robust shed, a concrete slab foundation is recommended. Mark the perimeter of your shed and dig a shallow trench. Pour and level the concrete, ensuring a perfectly flat surface. Allow ample time for the concrete to cure completely before proceeding.

Alternative Foundation Options

If a concrete slab is impractical, consider alternative foundation options such as gravel pads or pier blocks. A gravel pad involves laying down a layer of gravel and compacting it firmly. Pier blocks provide a solid base supported by individual blocks, reducing the need for extensive excavation. Remember to ensure a level and stable foundation for any chosen method.

Framing and Sheathing

Constructing the Frame

Once the foundation is set, build the shed's frame. Begin by constructing the floor frame, using pressure-treated lumber. Then, erect the walls, carefully ensuring squareness and plumbness at each corner. Use a level and plumb bob regularly to maintain accuracy. Reinforce the frame with bracing for extra stability.

Adding the Sheathing

Next, attach the sheathing. Plywood or OSB sheets are commonly used. Ensure proper overlap and secure them with nails or screws. Pay close attention to aligning the sheets correctly and spacing the fasteners appropriately. This step creates a solid surface for the siding and roofing.

Roofing and Siding

Installing the Roof

Now it's time for roof construction. Assemble the roof trusses or rafters according to your design. Carefully lift them into place and secure them to the top plate of the walls. Install sheathing over the trusses, creating a solid base for your chosen roofing material. Finally, install your shingles, metal roofing, or other chosen material following manufacturer instructions.

Applying the Siding

The final exterior step is installing the siding. Whether you're using vinyl, wood, or metal siding, follow the manufacturer's instructions carefully. Ensure proper overlap and secure the siding with nails or screws. Maintain consistent spacing and alignment for a professional finish.

Finishing Touches

Installing Doors and Windows

Now, install the doors and windows. This involves precise measurements and careful fitting. Use appropriate hardware and seal around the frames to prevent drafts and water leakage. Ensure the doors and windows operate smoothly and securely.

Adding Finishing Details

To complete your shed, consider adding finishing touches like painting or staining the exterior and interior. Install shelving and any other desired interior features. This will personalize your shed and make it more functional. A final cleanup leaves you with a stunning new addition to your property.

Building your own shed is a challenging but incredibly satisfying experience. With careful planning and attention to detail, you can create a valuable structure that will serve you for years to come.

Beginner-friendly backyard shed plans

Beginner-Friendly Backyard Shed Plans: A Comprehensive Guide

Constructing a backyard shed is a rewarding project that enhances both the functionality and aesthetic appeal of your property. While the prospect might initially seem daunting, with careful planning and execution, even novice DIY enthusiasts can successfully build their own shed. This comprehensive guide provides detailed, beginner-friendly plans, covering every step of the process from initial design considerations to final finishing touches. We will focus on a straightforward, robust design suitable for various skill levels.

Phase 1: Planning and Design

The foundation of any successful shed construction lies in meticulous planning. Before you even pick up a tool, dedicate ample time to designing your shed. This phase involves several key considerations.

1. Defining Your Shed's Purpose and Size

The first step is determining the primary function of your shed. Will it serve as storage for gardening tools and equipment? A workshop for small projects? Or a combination of both? The intended use directly impacts the required size. For beginners, a smaller shed (approximately 8ft x 6ft) is recommended due to its manageable size and reduced complexity.

2. Selecting the Right Location

Choose a location that is level, accessible, and compliant with local building codes and homeowner association regulations. Consider proximity to utility lines, drainage patterns, and sunlight exposure. Ensure adequate space for future access and maneuverability. A level, well-drained spot is crucial for a stable foundation.

3. Material Selection

For beginners, pressure-treated lumber is a highly recommended choice. Its resistance to rot and insect infestation simplifies maintenance and extends the shed's lifespan. Consider using standard dimensions (e.g., 2x4s, 2x6s) for easier construction and readily available materials. Hardware selection should also be planned in advance. High-quality screws and nails are essential for a secure and durable structure.

4. Obtaining Necessary Permits

Always check with your local authorities to determine whether a building permit is required for your shed project. Failing to obtain necessary permits can result in fines or even demolition orders. The permit application process might vary depending on your location, shed size, and building codes.

Phase 2: Foundation Construction

A solid foundation is paramount for the longevity and stability of your shed. Several options are available, each with varying levels of complexity.

1. Concrete Slab Foundation

This provides the most robust and level base. However, it requires specialized tools and materials, and can be more expensive and labor-intensive. For beginners, this might be best left to professionals or a more experienced DIYer.

2. Gravel Base Foundation

This is a simpler and more cost-effective alternative. It involves excavating a level area, laying down a layer of gravel, compacting it, and then placing pressure-treated lumber directly on the gravel. This method is suitable for lighter sheds and less demanding soil conditions. Ensure proper drainage is incorporated.

3. Concrete Pier Foundation

This is a compromise between the slab and gravel base. It involves pouring individual concrete piers at each corner and load-bearing points of the shed. These piers provide a stable base while minimizing the amount of concrete needed compared to a full slab.

Phase 3: Frame Construction

The frame forms the skeleton of your shed. Accuracy is key at this stage to ensure a square and structurally sound building.

1. Building the Floor Frame

Using your chosen pressure-treated lumber, construct a rectangular frame according to your dimensions. Ensure that all corners are square using a speed square or other measuring tools. Properly fasten the lumber using appropriate screws or nails. Lay down plywood sheeting on top of the frame for the flooring.

2. Erecting the Wall Frames

Construct individual wall frames, ensuring they are plumb and square. Use the appropriate size lumber based on the shed's dimensions and desired strength. Remember to account for door and window openings during the framing process. Pre-assembling the wall frames before lifting them onto the floor frame significantly streamlines the process.

3. Assembling the Roof Frame

The roof frame design can vary depending on personal preference and shed dimensions. Common options include a gable roof (triangular shape) or a shed roof (single slope). Construct the roof trusses or rafters according to your chosen design and secure them to the top plates of the wall frames. This is often the most complex part of framing, so take your time and ensure accuracy.

Phase 4: Sheathing and Roofing

Once the frame is complete, you can begin sheathing the walls and roof. This provides a weatherproof barrier and a surface for the exterior cladding.

1. Wall Sheathing

Use plywood or OSB (Oriented Strand Board) for sheathing the walls. Ensure that the sheets are properly fastened and aligned. Properly sealing all joints and gaps is crucial for weather resistance.

2. Roof Sheathing

Similarly, sheath the roof with plywood or OSB, ensuring proper overlap and secure fastening. This forms the base for the roofing material.

3. Roofing Material Installation

Choose a roofing material that suits your budget and aesthetic preferences. Asphalt shingles are a popular choice for beginners due to their ease of installation and affordability. Follow the manufacturer’s instructions carefully during installation.

Phase 5: Finishing Touches

The final phase involves adding the finishing touches to your shed, transforming it from a basic structure into a functional and appealing addition to your backyard.

1. Exterior Cladding

Apply exterior cladding, such as siding, to enhance the shed’s appearance and provide additional weather protection. Various materials are available, each offering unique benefits and aesthetic qualities.

2. Door and Window Installation

Install the pre-hung door and windows, ensuring they are properly aligned and sealed to prevent drafts and moisture penetration.

3. Interior Finishing

Consider adding interior finishing such as paint, shelving, or wall paneling to enhance functionality and aesthetics. This allows for customization to meet specific storage needs.

Conclusion

Building a backyard shed is a rewarding experience that provides valuable skills and a tangible accomplishment. While it demands time and effort, this beginner-friendly guide offers a clear pathway to successfully construct your own shed. Remember to prioritize safety, plan carefully, and take your time; the result will be a functional and attractive addition to your property for years to come. Always remember to consult professional resources and seek assistance when needed; don't hesitate to ask for help from more experienced DIYers if you encounter difficulties.

How to Build a Wood Pallet Shed: Simple Plans for Maximum Storage

How to Build a Wood Pallet Shed: Simple Plans for Maximum Storage

Hey there, fellow DIY enthusiasts! So you're thinking about building a shed, but the price tags at the big box stores are making your wallet weep? I get it. Building your own shed can be a fantastic way to save money and get exactly the storage space you need. And what's even better? You can do it using reclaimed wood pallets! Let's dive into how you can build a surprisingly sturdy and attractive shed using this readily available and budget-friendly material.

Planning Your Pallet Shed: Size and Location

Before you even think about grabbing a hammer, some careful planning is key. This isn't rocket science, but a bit of forethought will save you headaches down the line.

Choosing the Right Size

How much stuff do you need to store? A small shed might be perfect for gardening tools, while a larger one could house lawnmowers, bikes, and even a workbench. Think about your needs, and sketch out a basic plan. Remember that pallets are typically 48 inches wide and 40 inches deep, so your design will be dictated by pallet dimensions to a significant degree. Start with a simple rectangular shape for ease of construction; you can always get fancy later!

Picking the Perfect Spot

Where will your shed live? Make sure you have enough space, consider access for delivery of the pallets, and check your local building codes. You'll need a level surface, and consider sun exposure and drainage â€" you don't want a soggy shed! Ideally, a location near an existing power source will make future electrical work much simpler.

Gathering Your Materials: More Than Just Pallets

Okay, so you've got your plan and location sorted. Now let's talk materials. While pallets are the stars of the show, you'll need a few other things to bring your shed to life.

The Pallet Hunt

Source your pallets responsibly! Look for pallets marked "HT" (heat treated) â€" these are safe for indoor and outdoor use. Avoid pallets marked "MB" (methyl bromide treated) as they can contain harmful chemicals. You can often find free pallets behind businesses or construction sites, but always ask for permission first. You'll likely need quite a few â€" the exact number will depend on your shed's size.

Essential Tools and Materials

Besides the pallets, you’ll need:

- Measuring tape

- Level

- Hammer or nail gun (a nail gun will dramatically speed up the process!)

- Screws or nails (long, heavy-duty ones are best)

- Post hole diggers (if you are securing the shed to the ground)

- Concrete mix (if you are using concrete for the base)

- Saw (circular saw is ideal, but a hand saw will do the job if you're patient)

- Safety glasses and work gloves

- Optional: Roofing felt or tar paper for waterproofing

- Optional: Plywood or OSB for sheathing (for a more finished look)

- Optional: Paint or stain for weather protection and aesthetic appeal

Building Your Pallet Shed: A Step-by-Step Guide

Alright, let's build! This is a simplified guide, and adjustments may be necessary depending on your design and the condition of your pallets.

Creating the Foundation

A solid foundation is crucial. You have a few options: a simple gravel base, concrete blocks, or a poured concrete slab. For a basic shed, a leveled gravel base will suffice. For something more permanent, concrete blocks or a slab are recommended. Ensure your base is level before proceeding.

Constructing the Walls

Start by assembling the walls using the pallets. You may need to cut some pallets to fit your dimensions. Secure the pallets together using screws or nails. Remember to consider the door placement during this stage. You can create a door frame using extra pallet wood, or by carefully removing some sections from existing pallets.

Building the Roof

The roof design depends on your preferences and skills. A simple gable roof is easiest for beginners. You can construct the roof trusses using additional pallet wood or purchase pre-made trusses for a more structurally sound roof. Once the trusses are in place, cover them with roofing felt or tar paper for waterproofing and then add your chosen roofing material. Consider using inexpensive corrugated metal sheets.

Adding the Finishing Touches

Once the main structure is complete, it's time for the finishing touches. Consider adding a door, windows, and shelving. You can use extra pallet wood for these features. Don’t forget to weatherproof your shed with a coat of paint or stain to protect it from the elements and enhance its appearance. You might even consider adding a simple latch or lock to keep your belongings secure.

Addressing Potential Challenges

Building a pallet shed is a rewarding project, but you might run into some snags. Here are a few common issues and how to address them:

Uneven Pallets

Pallets can be uneven, so you may need to shim them during construction to ensure everything is level and plumb. Use small wood scraps to level out any inconsistencies.

Loose Nails and Screws

Use high-quality screws and nails and ensure they are properly secured. Consider predrilling pilot holes to prevent splitting the wood, especially with harder woods.

Weather Protection

Always use appropriate weatherproofing materials and techniques. Consider a sealant to prevent water damage and maintain the integrity of the structure for years to come.

Commonly Asked Questions

Let's tackle some frequent queries:

- Q: How long does it take to build a pallet shed? A: The time it takes depends on the size and complexity of your shed, your DIY experience, and the availability of your tools. A basic shed might take a weekend, while a larger, more complex one could take several days or even longer.

- Q: How much does it cost to build a pallet shed? A: The cost primarily depends on whether you can source free pallets. Otherwise, expect to pay a small amount per pallet. The other materials will add to the cost, but it should be significantly less expensive than a store-bought shed.

- Q: Are pallet sheds durable? A: While pallets aren't treated lumber, a well-constructed pallet shed can be surprisingly durable, especially if you properly weatherproof it. Its longevity will depend on the quality of the pallets used and your construction techniques.

- Q: Do I need any permits to build a shed? A: Building codes vary by location. Check with your local authorities to see if a permit is required for your shed project before you begin.

- Q: Can I add electricity to my pallet shed? A: Absolutely! This would require additional wiring and an electrical outlet, and it's always best to consult with an electrician or follow local electrical codes for a safe setup.

There you have it! Building your own pallet shed is a fantastic way to create valuable storage space while saving money and flexing your DIY muscles. Remember to prioritize safety, plan meticulously, and have fun with the process! Happy building!

Build an 8x10 shed with shelves and tool storage compartments

Building Your Dream 8x10 Shed: A Comprehensive Guide

Tired of tripping over garden tools and wrestling with overflowing storage bins? Imagine a neat, organized space where everything has its place. This guide will walk you through building your own 8x10 shed, complete with customized shelving and tool storage compartments, transforming clutter into order. We'll cover the planning, construction, and finishing touches, empowering you to create a functional and aesthetically pleasing addition to your property.

Planning Your Shed Project

Before you even pick up a hammer, meticulous planning is crucial. Start by securing the necessary permits from your local council; these requirements vary by location, so don't skip this step! Next, choose a suitable location on your property. Consider sunlight exposure, accessibility, and proximity to power sources if you plan on adding electrical outlets. Careful measurement is key: accurately determine the dimensions of your shed, accounting for the thickness of the building materials. Finally, create a detailed budget, encompassing all materials, tools, and any potential labor costs. A well-structured plan minimizes unexpected expenses and ensures a smooth construction process.

Choosing Your Materials

Selecting high-quality materials is essential for a durable and long-lasting shed. Pressure-treated lumber resists rot and insect damage, making it ideal for the shed's frame. For the siding, consider options like vinyl, metal, or wood, each with its own pros and cons regarding cost, maintenance, and aesthetic appeal. Choose sturdy roofing materials like asphalt shingles or metal roofing for weather protection. Don't forget about fasteners â€" galvanized screws and nails will resist rust and ensure a secure structure. Lastly, plan your shelving and storage components â€" plywood is a cost-effective and versatile choice for shelves, while plastic or metal containers provide durable tool storage solutions.

Constructing the Shed Frame

With your materials gathered and your plan finalized, it's time to build the shed's foundation. Begin by leveling the ground and creating a solid base using concrete piers or a wooden frame. Then, erect the frame using pressure-treated lumber, ensuring all corners are square and the frame is plumb. Precise cuts and accurate measurements will ensure a structurally sound building. Securely fasten the frame components with galvanized screws, paying close attention to bracing and reinforcement to withstand wind and snow loads. Remember to regularly check your work against your plans to ensure accuracy. This solid base forms the foundation for everything else.

Adding Walls and Roofing

Once the frame is complete, you can begin adding the walls. Attach your chosen siding material, ensuring proper overlap and sealing to prevent water damage. Install windows and doors, selecting options that complement your shed's design and provide adequate ventilation. Roof construction follows, starting with the trusses or rafters, carefully positioned and secured to the frame. Add your chosen roofing material, ensuring proper overlapping and sealing to prevent leaks. Thorough waterproofing at this stage prevents future headaches. Take your time; attention to detail here significantly impacts the longevity and weather resistance of your shed.

Integrating Shelving and Tool Storage

This is where your shed transforms from a basic structure into a highly functional workspace. Before installing the interior walls, plan the placement of your shelving units and tool storage compartments. Measure and cut plywood for shelving, ensuring that the shelves are securely attached to the wall studs. Consider incorporating adjustable shelving to accommodate items of varying heights. For tool storage, you can build custom compartments using plywood or utilize pre-fabricated units for convenience. Consider incorporating features like pegboards for hanging tools and drawers for smaller items. A well-organized interior significantly improves the usability of your shed.

Finishing Touches

Once the shelving and storage are in place, add the finishing touches. Apply exterior paint or sealant to protect the wood and enhance the shed's aesthetic appeal. Consider adding trim and molding for a professional look. Install electrical wiring and outlets if desired, ensuring compliance with local electrical codes. This step is vital for safety. Finally, clean the shed thoroughly and organize your tools and equipment. Adding a lock to your shed's door provides crucial security for your valuable tools and equipment. Stand back and admire your handiwork â€" you've successfully built a functional and organized storage solution!